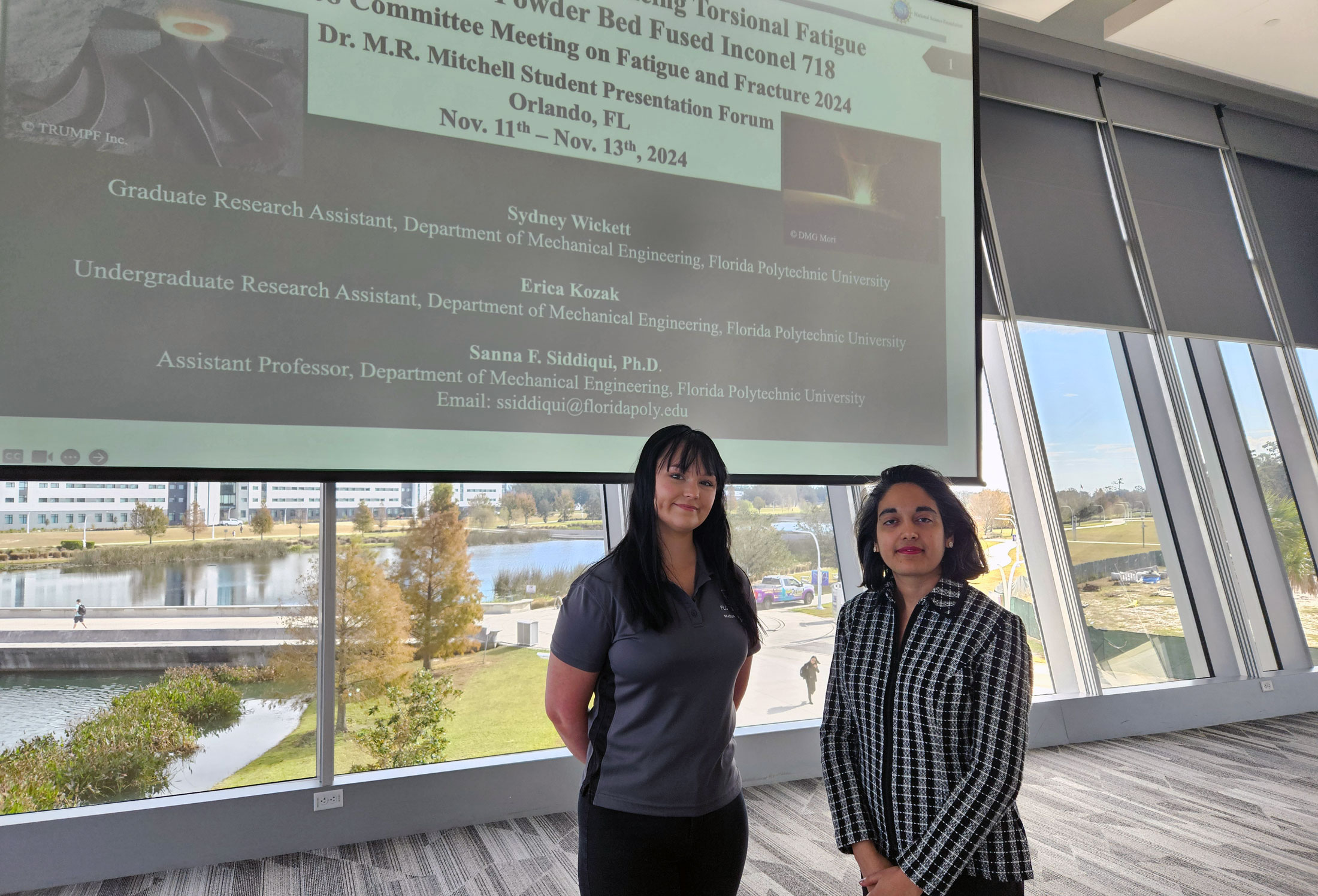

Sydney Wickett (left), graduate research assistant for mechanical engineering at Florida Polytechnic University, and Dr. Sanna F. Siddiqui, assistant professor of mechanical engineering, display the presentation Wickett delivered at the American Standard for Testing Materials (ASTM) E08 Fatigue and Fracture Committee Dr. M.R. Mitchell Student Forum in Orlando, Florida, in November. Wickett won the forum, besting top scholars from around the country.

Florida Polytechnic University graduate research assistant Sydney Wickett recently captured top honors at the American Standard for Testing Materials (ASTM) E08 Fatigue and Fracture Committee Dr. M.R. Mitchell Student Forum in Orlando, Florida. The forum is among the most significant for engineers and researcher experts in fatigue and fracture mechanics.

Wickett’s presentation, based on research funded by a $150,000 National Science Foundation (NSF) grant awarded to Dr. Sanna F. Siddiqui, focused on assessing the microstructural defects introduced through the laser powder bed fusion additive manufacturing process on the service life of 3D-printed nickel-based superalloy components used in applications such as rockets and jet engines. Siddiqui is an assistant professor of mechanical engineering at the University.

Wickett emerged as the sole winner at the student forum in November, representing a significant achievement for Florida Poly at the national level. The research presented examined critical limitations of these 3D-printed metal parts, exploring the superalloy materials’ durability and life, subject to cyclic twisting loads – or torsional fatigue – at high temperatures, and the role of additively manufactured induced microstructural defects on their resulting performance.

“We were looking at a material that has been 3D printed, layer by layer, to detect defects in those parts before they can be used on a wider scale," Wickett said. “We’re looking at how the part reacts to being subject to repetitive twisting loads.”

The research revealed concerns about manufacturing these parts for the aerospace sector.

“There is a reduction observed in the overall torsional fatigue life observed for these parts as compared with their conventionally manufactured counterpart, and that’s the importance of the results,” Siddiqui said. “The laser powder bed fusion additive manufacturing process introduces microstructural defects, and the presence of those defects, along with material phase changes occurring at high temperature, limits mechanical performance subject to torsional fatigue loading.”

The research findings are a big step toward breakthroughs in 3D-printed parts for multiple advanced applications, Siddiqui said. She received a prestigious NSF CAREER award in 2024 to continue advancing her research.

“I’m very excited because these research findings contribute to the next phase of this research, with one aspect of my NSF CAREER award exploring variation in torsional fatigue performance of these materials developed through the very low-cost material extrusion additive manufacturing process ,” Siddiqui said.

“We're not achieving the service life expectancy for the part that we expect manufacturing through the laser powder bed fusion additive manufacturing process, so the next phase is to delve into a more low-cost additive manufacturing approach, to yield comparable if not enhanced mechanical performance, as compared with conventional manufacturing techniques and existing metal additive manufacturing technologies.”

Undergraduate research assistant Erica Kozak also participated in the work.

Wickett, who received her bachelor’s degree in mechanical engineering from Florida Poly in May 2024, is set to receive her master’s degree in May. She is part of the University’s 4+1 Master’s Degree Program, which allows students to earn master’s credit alongside their undergraduate degree, shortening their time to an advanced degree by about a year.

Wickett has been accepted to the University of Central Florida’s Ph.D. program in mechanical engineering, where she plans to continue research work and pursue a career in academia.

“I wasn’t even going to go into research is the funny part,” Wickett said. “But after I started, there was no going back.”

Contact:

Lydia Guzmán

Director of Communications

863-874-8557